Custom-made ionizing dedusting and cleaning system for plastic films, cardboards

Particles smaller than 3mm

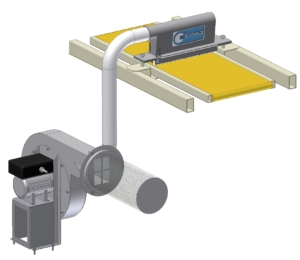

ECOVAC 5

The ECOVAC 5 custom-made ionising dedusting systems is used to remove dust with a diameter up to 3 mm..

n order to achieve optimum dust removal from a single-sided film, it is imperative to implement three inseparable actions:

- A mechanical force for the separation of the particles from the substrate

- Air ionization for the elimination of electrostatic attraction

- A suction for the evacuation of particles

The film touches the squeegee in the centre, i.e. between the suction slots and the ionizing bars. This action lifts the particles and causes their electrostatic charge to appear. This charge will then be neutralized by the antistatic bars placed at the inlet and outlet of the system. Finally, the two suction slots on either side of the squeegee allow the collection of particles that have accumulated before and after the squeegee.

Only the action of these three combined phenomena guarantees optimal dust removal of particles and/or dust visible/non-visible to the naked eye present on the film.

On the ECOVAC 5, the ionisation tips are connected to the high voltage source by a capacitive device, thus limiting the current to a few micro-amperes. This means that these devices do not present any danger if the operator comes into contact with the live tips.